Technology

The technological process of recycling plastic waste typically starts after the selection of wastes collected from waste managers and collectors, broken down to material types, which are then handed over in bales and compacted to businesses engaged in plastic recycling. Plastic waste types received by the Company for recycling: PE, PP, HIPS.

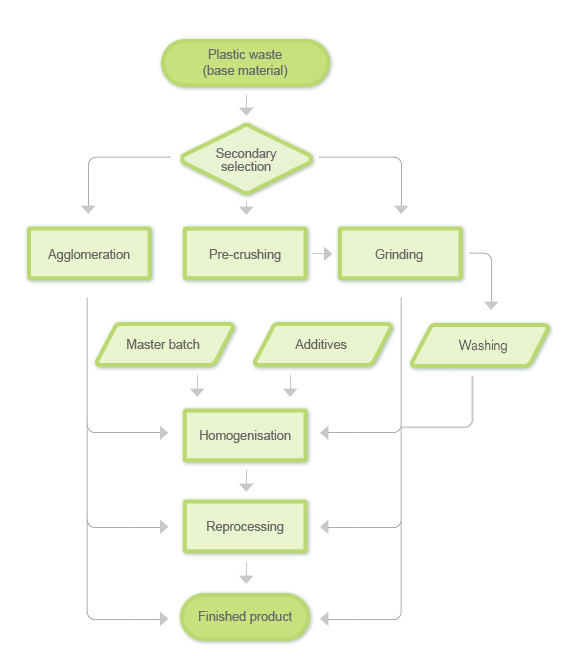

The incoming plastic wastes are processed in the preparation plant depending on the types of materials, or are, in justified cases, subjected to secondary selection prior to processing. This latter process is carried out if, for instance, the secondary selection from multicoloured foil bales is performed by colour or, in case of crates, by polyethylene or polypropylene material.

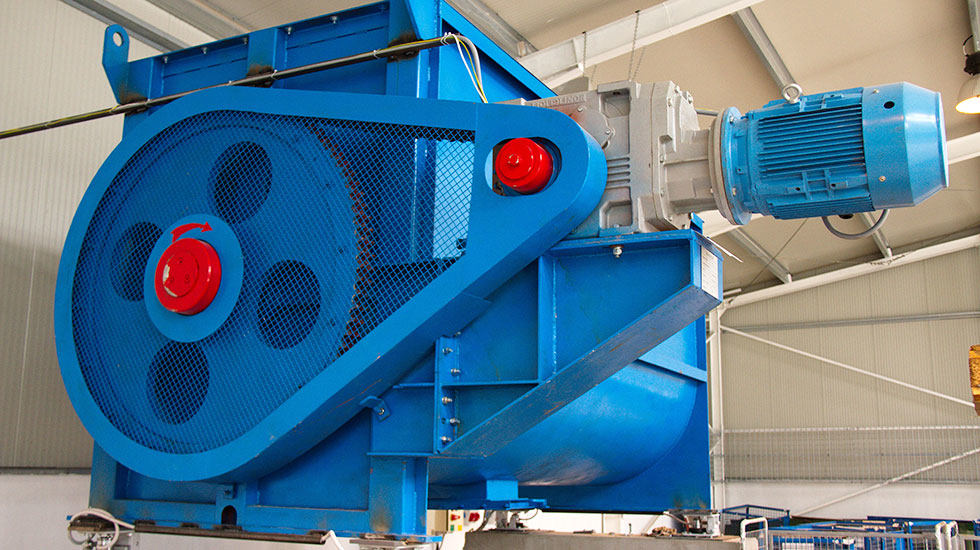

The first phase of recycling wastes of foil type is the so-called agglomeration, during which the waste material becomes practically ground, but as a result of cooling carried out with the water entered in the process the crushed material becomes a so-called agglomerate typically taking a gall-like and not a plate-like form. The first step of recycling larger wastes (drums, pots, dustbins or pallets) starts with direct pre-crushing, which is followed by grinding. In the course of this the waste is put as ground material with a surface of 15 to 20 mm into large sacks placed on a stand.

Regrind

Washing

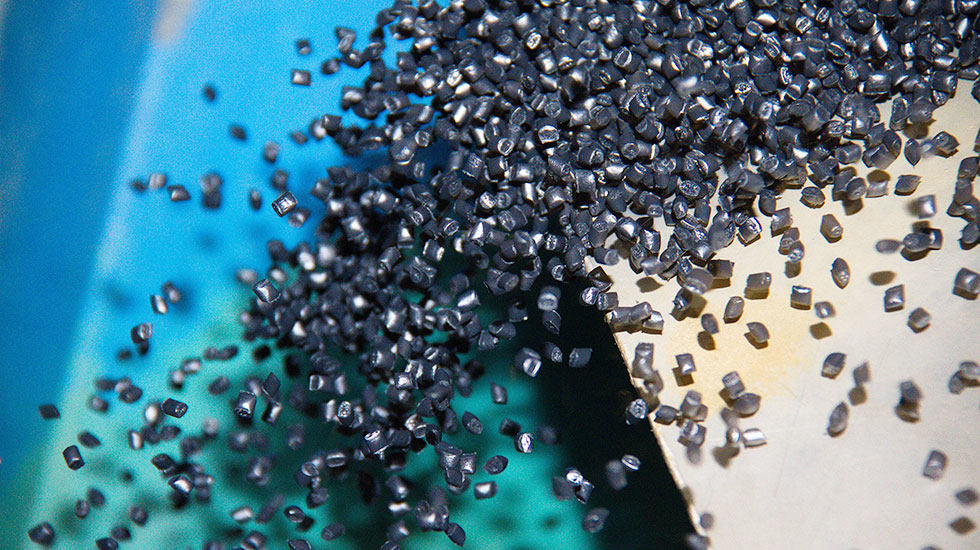

The second step of plastic recycling is the preparation of semi-finished materials produced in the preparation plant for granulation, which is in line with the actual demand of customers for secondary raw materials. For the production of recycled plastic re-granulate with appropriate quality, mixing or homogenisation takes place in accordance with the recipes applied in the plant, using a master batch and other additives. Its primary purpose is that the re-granulate to be produced has identical physical properties, which is a priority from the aspect of producing finished products later on. The homogenised dry mix is processed in a melted state on the screw extruder machinery. The final stage of this process is the crusher-confectioned re-granulate (HDPE, LDPE, PP, PS), which becomes, after packing, suitable, as recycled plastic, for producing finished products at plastic processers purchasing this material.

Sampling and controlling the basic physical properties per production always take place in accordance with the quality management system put in place.

Our base materials have technical and safety data sheets.